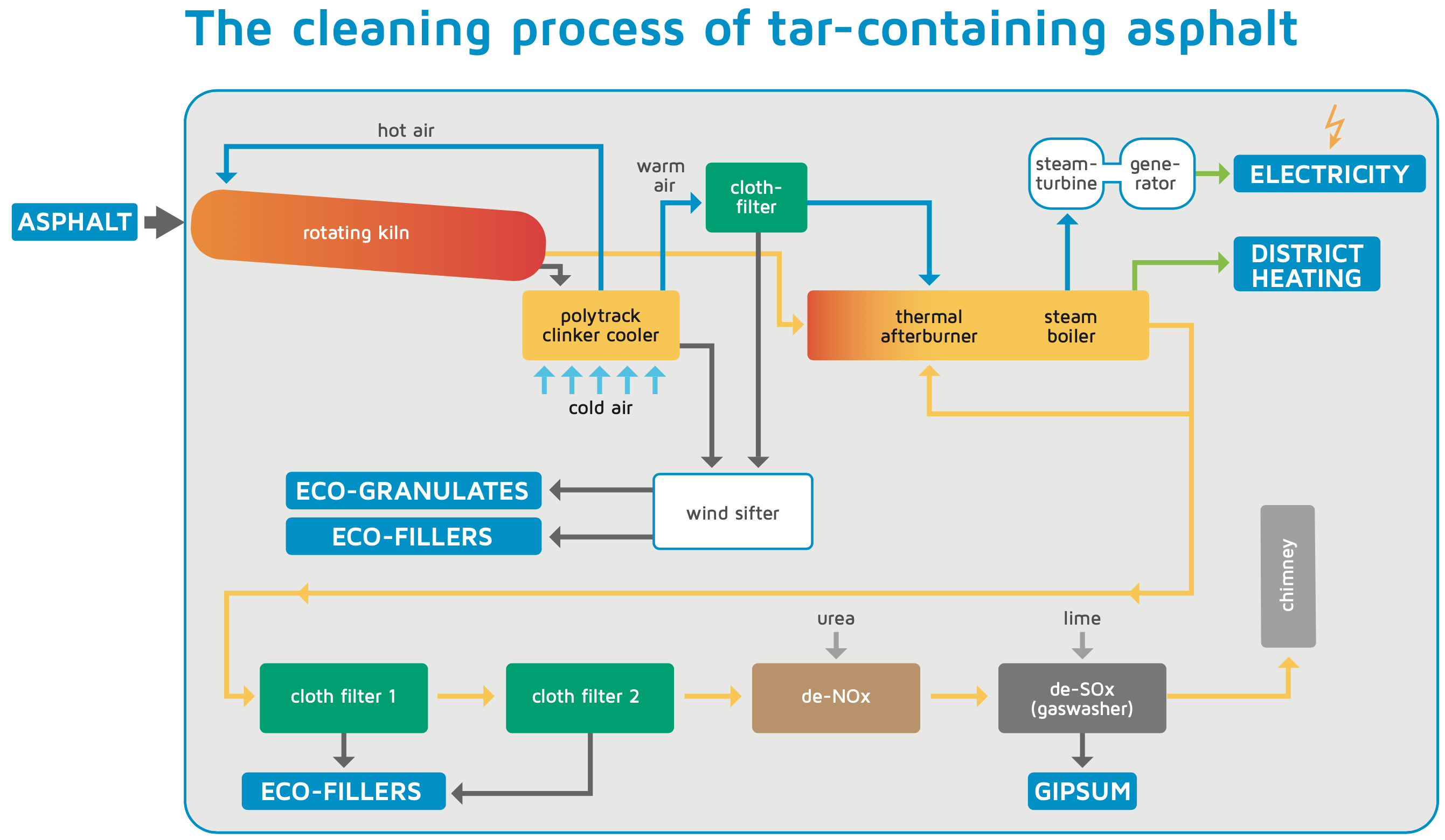

The cleaning process of tar-containing asphalt

Tar-containing asphalt consists of the raw materials sand, granulate, filler and tar as a binding agent. By heating to a high temperature, the tar is completely destroyed and the resulting flue gases are scrubbed. What remains is ECO sand, ECO granulate and ECO filler.

1. Pre-treatment of the asphalt

The tar-containing asphalt released during reconstruction of roads is delivered to REKO by ship or by truck. The tar-containing asphalt is crushed in a crusher to form Tar Asphalt Granulate. After this, the cleaning process can begin.

2. Incineration drums

The tar-containing asphalt is fed into a rotating incineration drum. At the front of the drum is a burner that heats the material to a temperature of 850 to 1000 °C. At this temperature, all pollution present is completely removed.

3. Cooling process

After the incineration drum, the cleaned material has a high temperature. This material is cooled by cold air. The outdoor air heated up in this process is returned to the front of the incineration drum as combustion air. This way the heated outside air is put to good use, reducing overall gas consumption in the system.

4. Cleaning the released flue gases

The flue gases released during the combustion process are cleaned of fine dusts, nitrogen oxide and sulphur oxide. The scrubbing of flue gases released during the thermal cleaning of tar-containing asphalt is a technologically advanced process.

5. Afterburner and energy recovery

The afterburner reheats all released flue gases. The hot gases are then passed through a boiler where they transfer their heat and produce steam. The steam is passed through a steam turbine, which in turn drives a generator that converts the energy into electricity. The electricity generated by both thermal treatment plants is more than sufficient to supply a city of approx. 100,000 inhabitants with electricity. The plants also have the ability to supply heat for district heating.

6. Dust collectors

After cooling, the gases are cleaned of dust in dust collectors. The dust released by these collectors is sold as certified filler under the name ECO filler and is used in the concrete and asphalt industry.

7. DeNOx (catalyst)

After dust collection, the gases pass through a DeNOx plant. In this unit, nitrogen oxide in the flue gases is converted into harmless atmospheric nitrogen (N2) and oxygen.

8. Gas scrubber

Coal tar has a high sulphur content. Burning it produces sulphur oxide. As a final step in the process, the flue gases are therefore treated in a so-called gas scrubber. By scrubbing the gases with water in which lime has been dissolved, the sulphur oxide present is converted via a chemical reaction into gypsum. The moisture is removed from the gypsum in a press, after which it is suitable for high-quality application in various building products.

9. Controls

Each stage of the cleaning process is monitored and controlled in a central control room. Any deviation, is detected in real time and corrected if necessary. This guarantees a high-quality end product, but also, it ensures there are no excess emissions and we always meet the environmental emission requirements.

10. Circular economy

After the thermal cleaning process, all materials are used again for 100% as high-quality raw materials. No residues remain. Our goal is to produce high-quality raw materials from tar-containing Asphalt and which can be used over and over again in the asphalt and concrete industry. This means that the loop is completely closed, there are no residual for which is no high-value destination.